Design

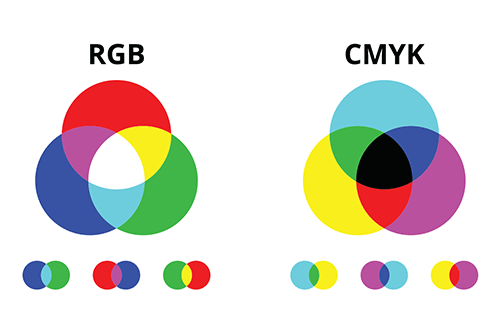

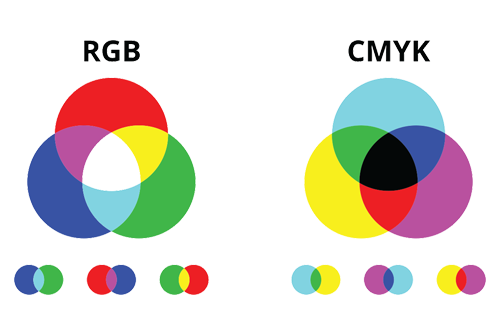

RGB and CMYK are two different color systems. You may know that CMYK is used for printing and RGB is used for web images and digital design for digital devices – TVs, computers, phones. What is the difference between them and why should each color palette be used as intended?

RGB - nature and features

In the RGB system, the basic colors in the light spectrum are blue light (red), green and blue. When these are mixed (with a value of 255 each), the result is white light. When this value is zero, it means that there is no light at all and the result is dark – I will say – black.

An important feature of RGB is that colors are produced by addition. When you add red, green and blue light to black – the absence of light (color) – you get the desired color and the more you add, the brighter the color you get (to white).

Because digital devices build images by mixing lights, RGB is the color mode used in digital graphic design.

CMYK - nature and features

The basis of the CMYK system are the pigments – light blue (cyan), pink-red (magenta), yellow (yellow) and black (K-key). Mixing them in different proportions produces the whole color gamut.

However, unlike RGB, it is obtained by subtraction. When 100% cyan, magenta and yellow are mixed, black is obtained. Black is generally called, though in practice it is more of a dirty brown. That is why the fourth color, black, is added. The greater the percentage of the primary colors represented, the more the new color absorbs light and is darker. As each of the primaries is reduced, lighter derivatives are produced.

Don’t think that if magenta, cyan, yellow and black are represented by 0%, there will be white on the print. There just won’t be any color, and if you print – say – on yellow paper, there will be an uncovered yellow spot in that spot. That’s why you usually print on white.

You may have noticed that the base colors are cyan, magenta, yellow, and black, but instead of writing the color model as CMY-B, we write it as CMYK. This is because in this case black is called Key and its job is to provide color density.

CMYK is designed for printing with inks and its professional use ensures printed materials with vivid and clear colors. In fact – when printing, it only appears that the four colors are printed on top of each other. Rather, multiple small dots of color are printed side by side and their combinations give the specific tones and halftones – just as the raster in black and white printing creates the illusion of different shades of grey.

Spheres of application

In graphic design, both color mixing modes are used. But as already mentioned – they have specific areas of application.

Work with RGB when preparing a design for:

web and apps;

– branding projects – online advertising,

– corporate identity for online presentation;

– social media – photos, profiles, illustrative images;

– visual content – infographics, digital graphics, videos.

CMYK is the mode of working on print projects:

– books, magazines, catalogs,leaflets, posters, etc;

– goods with a printed element – company workwear, advertising T-shirts and hats, etc;

– basic materials for the production process – packaging, menus, etc.

The quality of color application is controlled by specially developed control scales.

Why we need to transform RGB to CMYK

RGB colors are bright and sparkling. But printing technology is designed to work with CMYK. If you design your print project in RGB, it will look one way on the screen. But if you don’t convert them to CMYK, printed, they will look different. Particularly saturated, bright colors will lose their brightness and vibrancy, become duller and more impersonal. Overall, maybe the image won’t look bad, but it definitely won’t be what’s on your screen. So convert in prepress and do your best to preserve the vibrancy of the color. Before sending your files to print, check what color mode they are in.

One more thing – even if you’ve converted the file to CMYK, it’s likely that the finished printed product will look different than it does on the monitor. This is due to the specifics of the color calibration technique.

Before we proceed with printing, we can make a color proof for you that will be as close to the final product as possible. And for any uncertainty or hesitation about color conversion, contact our graphic designers. They will help you.

Check our price: it’s free and it only takes seconds!