Why are some books produced with softcovers and others with hardcovers?

Why would you choose a hardcover rather than a softcover, which is more economical and easier to produce? Many criteria influence the choice of bookbinding: content, graphic design, target audience, sale price, etc.

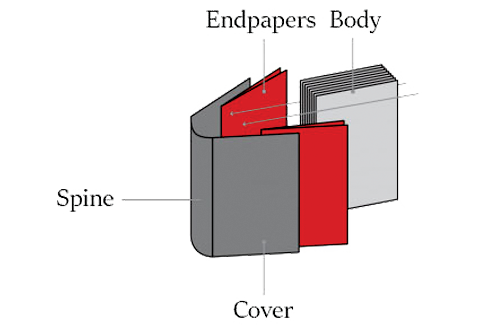

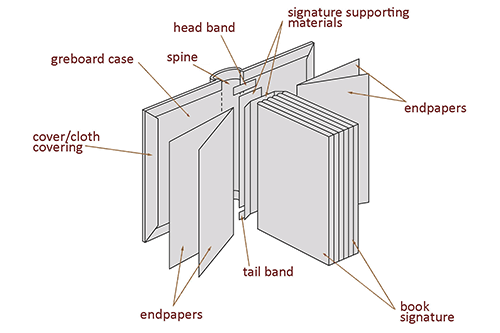

Soft covers are paper-bound books (glued or stitched) where the inside block and the back of the cover adhere together. For hardcovers, the endpapers join the inside and the cover together. Various elements are added, such as the endpapers, the headbands and the tail bands, the covering material, the card, the back, and the bookmark.

If you opt for a softcover book, your choice is simple: an interior and a thick paper cover with a density usually between 40 lbs and 130 lbs, with flaps in option.

But if you opt for a hardcover book, you will invest more in the end product, excellent choice! In the digital age, the physical 3D presence can make a difference. With a hardcover book, you get visible high quality, volume, and weight thanks to the thickness of the binding, the touch, and the smell of quality materials. Hardback is the most secure option: it is durable, prestigious, and timeless.

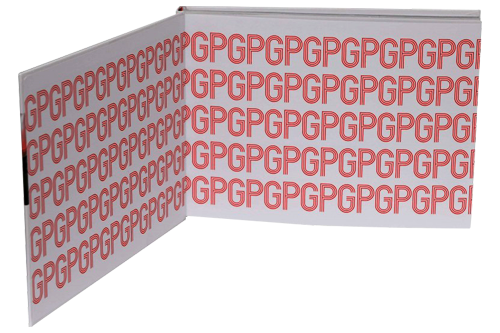

The Endpapers

Their primary function is to join the inside to the cover and to do so efficiently.

The first of the front endpapers and the last of the back endpapers are always clear because of their lamination onto the second and third of the hardcover.

Their number is unchangeable, with four (4) pages at the front and another four (4) pages at the end.

The Cover card

The thickness may be 1.5mm – 2mm – 2.2mm – 2.5mm – 3mm, 15/10 – 20/10, etc. It often depends on the thickness of the interior. The principle is that the thicker the interior volume is, the more weight is added to the card. The most common thicknesses are 2, 2.5, and 3mm.

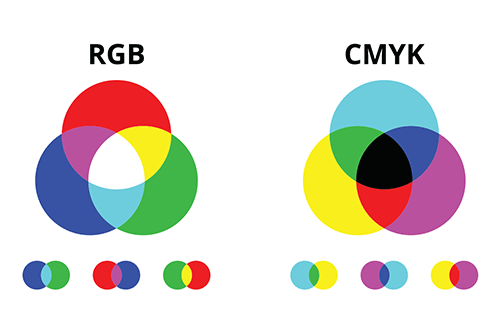

Usually covered with 100 lbs coated paper, the cover allows offset printing.

Other offset-type papers are available for complex production. The chosen offset paper must be sufficiently flexible not to crack in the corners. We recommend Olin Smooth, Olin Rough, Popset, Cotton Laid, Buckram, Via Felt, and Via Linen.

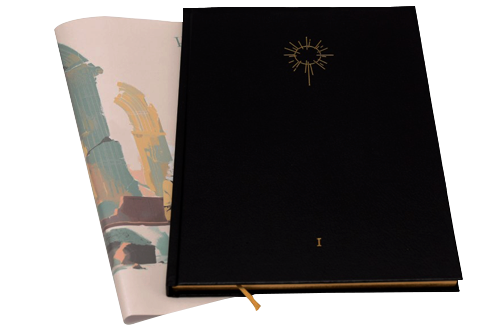

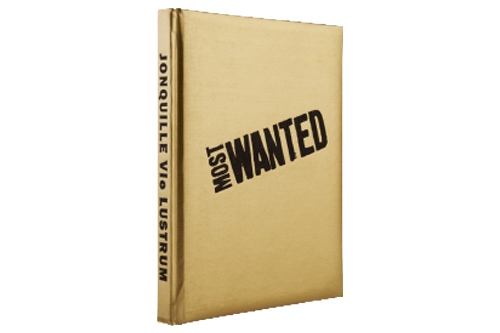

Instead of paper, you can opt for cloth fabric, leather, or fake leather.

A wide choice is available, and we invite you to check our fabric catalog in the online viewer. You can also visit our manufacturer website, Winter and Company, which offers fabrics such as Skivertex, Novalite, Wibalin, Peltouch, Geltex, Napura, Toile du Marais, Pellaq, Synth3, and Leos Nachfolger. Fabric covers are unprintable, but embossing, relief printing, hot stamping, or screen printing will be applied instead.

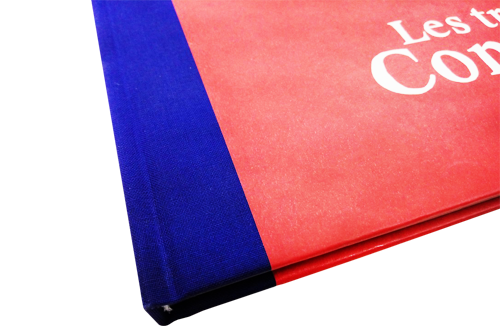

Cloth/Fake Leather

Hybrid option

You can also opt for a hybrid option with fabric on the spine and paper on the covering. A beautiful compromise, the choice of color also adds an original touch to the design.

Raw and Natural state

One option also is leaving the card to its raw and natural look without covering it. It is a trend in the world of art and alternative graphic novels.

The Foam

You can add foam between the card and the paper on the top. It gives volume and a pleasant sensation at the touch. This option is ideal for younger readers or users because it also protects the book.

The Spine

The spine of a hardcover book can be straight or round. There needs to be a minimum thickness of 15mm for a round back. It holds large book pages together to mitigate their thickness.

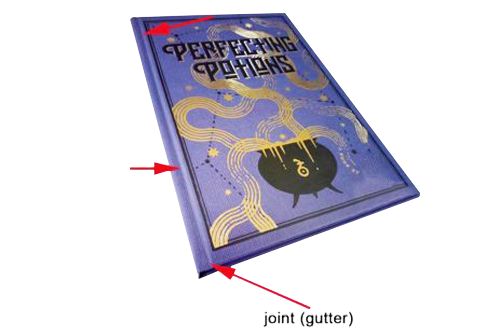

The Gutter

The gutter gives extra space to the inside opening and the covering design. Generally straight shaped, it can also be lightly curved when the back is round.

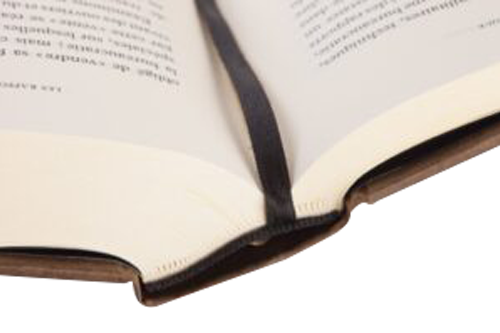

The headband and the tail band

They are small pieces of fabric glued to the head and the tail of the hardcover book, which is usually black or white but can be of different colors, adding to the style and aesthetics of the product. They are integral parts of the cover card when the back exceeds 10 mm.

The Bookmark

The bookmark is another version of a page marker, a little cloth ribbon glued under the headband at the head of the book. It makes it easier to find a specific page in the book. For greater sophistication, choose two bookmarks in different colors. The bookmark has a rightful place in a beautiful publication and a blend of practicality and elegance.

Spiral Binding

Spiral bound binds the interior and the cover without glue. In this case, you will have both the solidity of the rigid card and the 360⁰ opening of the spiral. It is a binding choice often found in diaries, textbooks, and cookbooks.

In the following, you will see the possible choices for each element of your hardcover book according to its page count:

Choosing between a soft cover and a hard cover is not always evident.

Budget: a hardcover indeed represents a more expensive solution. In the case of low page counts, the cost of manufacturing the cover may be greater than the cost of production of the whole inner block.

Specifications: A4 size, 96 pages + (8 non-printed endpapers), matte lamination, four-sided recto verso printing on coated paper 90 lbs, 1,000 copies, delivery included.

Rates: Softcover, perfect bound: $ 4217, Softcover, tread sewn bound: $ 5254, Hardcover, case-bound, 2mm (20/10): $ 9308

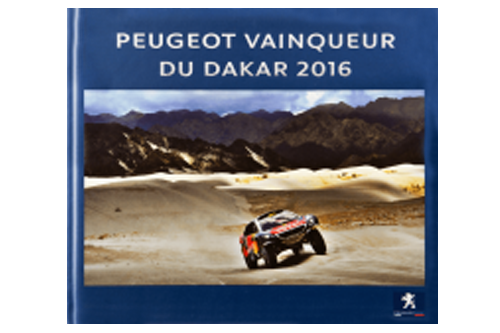

Content: Some book contents deserve a hardcover. When we find ourselves in the realm of beautiful books, a hardcover is a must.

Target market: depending on the intended use for the work, its strength is a primary factor. For example, the best option for children’s books is hardcover. It guarantees the durability of the book.

Commercial strategy: Everything you need to embellish a printed product is available with a hardcover. The visual impact of a product remains crucial today. A book in hardcover can make all the difference.

Pulsio Print advisors are available to answer your questions and give you all the support you need.

Check our price: it’s free and it only takes seconds!