As with an objet d’art, gilding enhances the value of a book and improves its visibility in bookstores. It is one of the most upscale finishes available. Until recently, the only way to carry out this process was hot stamping, which consists of depositing a metal film on the cover using a block with all the gilding elements to be stamped, a heat source that can reach 200° C and an enormous pressure that can be as much as a ton!

Depending on the number of elements to be gilded, the process can be performed in several passes on the same machine and when embossing is required, despite the precise settings a gap between the embossed element and the gilding is very possible. Relief on the inside of the cover due to embossing is inevitable.

Silk Foil

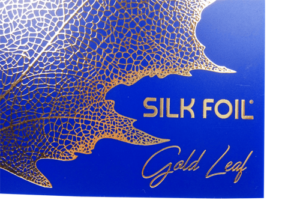

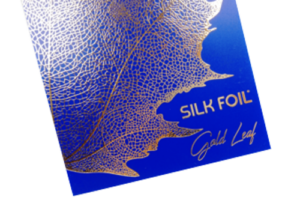

Today, an alternative exists and Pulsio Print is delighted to offer it to its customers: “Silk Foil” gilding! This innovative process represents a combination of screen printing using UV glues and hot stamping. Both processes are managed with high precision by digital modules. The hot stamping is done using a special silicone plate, as fine as silk, hence the name of the process.

“Silk Foil” makes hot stampings with a curved effect without prior embossing. For this reason, this innovative gilding is also called “3D Gold”. In addition to a delicate relief to the touch, it offers an incomparable brilliance, far more vivid than that of a standard hot stamping and without the embossed effect on the back of the cover.

What makes the new “Silk Foil” an interesting process?

Convenience and speed: it allows us to achieve attractive gilding and relief effects on a single machine. Even with the two necessary manufacturing phases, the process is much faster than the two separate operations – the embossing and hot stamping of conventional gilding. And that saves you time.

Freedom in the choice of paper / cardboard: the relief obtained without embossing allows you to apply “Silk Foil” on thick sheets as well as on very thin sheets, thanks to the UV glue that creates this relief. This is impossible to do in classic gilding.

Economy: you can forget about the expense of preparing blocks for embossing and hot stamping.

The environment: “Silk Foil” technology is practically waste-free – no more setup wastage for embossing and hot stamping. The special film that adheres only to the details you have chosen to add value to is completely used up, unlike the “classic” hot-stamping film whose unapplied parts remain unusable.

Quality: the perfect adhesion between the glue and the silicone film, even on a tiny surface, avoids micro-cracks in the gilding and the removal of film of standard hot stamping. The “Silk Foil” gilded elements, even the most delicate ones, have homogeneous, smooth and stable surfaces and edges. The nature of the process preserves any gap between embossing and gilding, even on extremely fine lines – a quality that is difficult to achieve with the traditional “embossing + hot stamping” combination.

Wide choice of colours: gold, silver, metallic, copper, light copper, black, light blue, blue, red, pink, green.

Durability: “classic” gilding that is not protected by varnish is susceptible to wear. “Silk Foil” fixed by its UV glue is not only long-lasting, but it also allows for the possibility of cleaning.

Silk Foil can also be applied to plastic, wood, leather, glass, etc. This gives you an additional opportunity to duplicate certain elements of your cover on promotional items during a major marketing campaign.

The application of “Silk Foil” gives aesthetically attractive and irresistible results. It’s wonderful gilding!

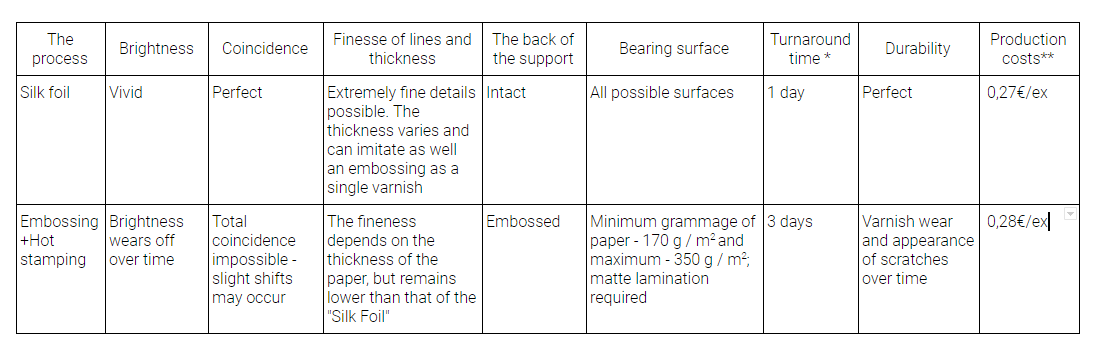

In the table below you have a comparison of “Silk Foil” and classic hot stamping with embossing.

Click to increase the size of the image.

* The technical details, which make each process more or less difficult to apply, but which do not directly concern the customer (for example: the inevitable elaboration of a block for gilding and/or a matrix for the embossing, change of machines, sheet yield used for cushioning or otherwise) are indicated and translated in the table as differences in “turnaround time”.

** Dimensions for gilding / silk foil of 100 x 100 mm, on cover A5, print run 1000 copies…

To make the best choice for your project between classic gilding and “Silk Foil”, we recommend that you contact a Pulsio Print Customer Advisor. According to your files/project and with the help of our pre-press service, they will advise you on feasibility and the best choice. We advise you to avoid overdoing special effects. “Silk Foil” is a sufficient process for attracting the customer’s attention while reducing your production costs and manufacturing time.

Check our price: it’s free and it only takes seconds!