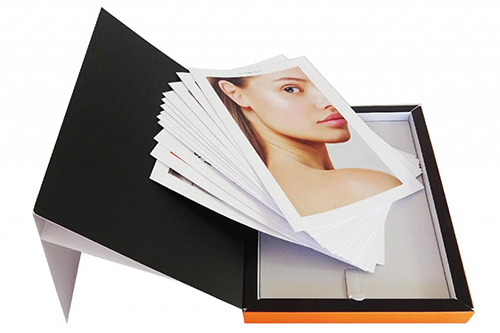

Lamination: optimal protection with a refined appearance

The true brand image of a publisher, laminating is the process of applying a clear plasticized protective film (polypropylene, cellulose acetate or polyester) to an entire printed surface. Generally used for covers, it will protect the document from possible alterations, preserve it from wear and above all embellish it by reinforcing its quality. Applicable on all papers from 170g, it can be matte, gloss or satin.

Appreciated for the refined and sober effect that it provides, matte lamination, while protecting the work, admirably accentuates the brilliance and contrast of the colours involved, and is perfect for art books or prestige items.

Reflecting light, gloss lamination enhances colours by accentuating the depth of blacks, and gives a bright, glowing appearance. Its sparkling effect makes it the ideal finish for any book cover.

Called “soft touch” or “peach skin”, satin lamination gives excellent protection while providing a pleasant feeling in the hand, silky and soft. An original mark of quality that only this first-rate finish can offer.

Laminating techniques

Applied with the help of a machine, lamination can be effected by two different processes.

Thermal or dry laminating is done with a film previously coated with an adhesive, which is applied by pressure using a roller heated to 130 °C. Easy to use, this technique has the advantage of laminating a document at a speed of 50 to 150 metres per minute, allowing a gain in productivity. It is also environmentally-friendly.

Traditional or wet laminating involves using a machine to coat the film with adhesive before applying it to the paper to be laminated. An older process, this technique can be performed either with UV glue, water-based glue, solvent-free glue or solvent glue (although this last is hardly ever used any more because of its toxicity).

Selective varnish

Matt lamination + selective varnish

Selective varnish with volume

Soft Touch + selective varnish with volume

Selective varnish: a striking visual effect

This finish consists of applying a gloss varnish on particular areas of a printed medium to highlight them with a contrast effect. Added to specific areas of a cover or leaflet, selective varnish gives a striking 3-D effect to a title, a name, a logo, a graphic element or a photo. Adding real value, the great visual effect of this finish gives an item an obvious aesthetic appearance while also giving it a luxurious look and feel.

Matte lamination + selective varnish: the top of the range of finishes

Considered a finish of choice, the application of a selective gloss varnish on matte lamination is a combination that delivers a sublime result. This exemplary process strongly accentuates the contrast between the matt rendering of the lamination and the gloss of the varnish, making the highlighted areas of varnish stand out, visible at first glance. To intensify the effect, it is advisable to use it on dark coloured backgrounds. This finish guarantees a significant visual impact and adds a new dimension to the printed document. Offering a high-quality and particularly luxurious rendition, it is recommended for leaflets, luxury magazines, book covers and works of art.

Selective varnish with volume: a new dimension

With a thicker texture, this selective varnish adds volume to the parts of the document to which it is applied. Giving an embossed appearance, it allows for the bringing into relief of an important element of a cover for example, and adds an element of vitality and a new dimension to the printing.

Soft Touch laminating + selective varnish with volume: a luxurious finish

Combining the silky and agreeable feel of Soft Touch laminating with the 3-D effect of selective varnish with volume, this finish gives your prints appropriate protection while offering an original look, incomparable volume and a luxurious appearance. The combination of these two processes makes it possible to accentuate the gloss and impact of the typographic elements on which the selective varnish with volume is applied, thanks to a contrasting effect with the matte appearance of the Soft Touch lamination. Intended for highlighting text, logos or graphic elements, especially on covers, this very high-end finish is suitable for media with a minimum weight of 350g.

Tips for preparing files for lamination and selective varnish

While adding value to your printing, selective varnish is nevertheless a technique which requires great precision and meticulous preparation. Two files need to be supplied, one in four-colour with cut lines, and the other separately, conceived as a fifth colour with 100% solid black on the elements to be varnished. Overlaying the two files will determine the areas where the varnish will be applied. It is advisable to make these files with professional DTP software such as Photoshop, Illustrator or InDesign, to make sure that they are perfectly superimposed and comply with professional printing standards.

Need advice?

With its strong creative and technical know-how, Pulsio Print will accompany you in your quest and offer quality services appropriate to your needs. Our expert consultants are at your disposal to advise you and guide you in your search for the best option to add value to all your creations!

Check our price: it’s free and it only takes seconds!