Cardboard Floor Display for Point-of-Sale/Advertising with custom design and printing

Point-of- sale advertising display is a strategic way for businesses to promote their newest and most favorable products! You can try drawing the attention of customers with our products, some of which are: cardboard shelves, PVC shelves, boxes and packaging.

– Easy to assemble, reducing the amount of time spent on merchandising.

– Lightweight so they can be moved around the shop floor easily.

– Flat packed for low distribution/transportation and storage cost.

– Durable enough to hold a range of merchandise

Check our price: it’s free and it only takes seconds!

Express manufacturing & delivery even for complex projects

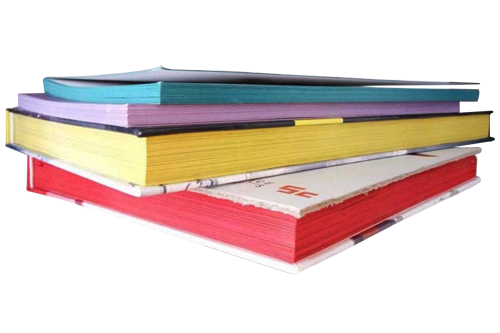

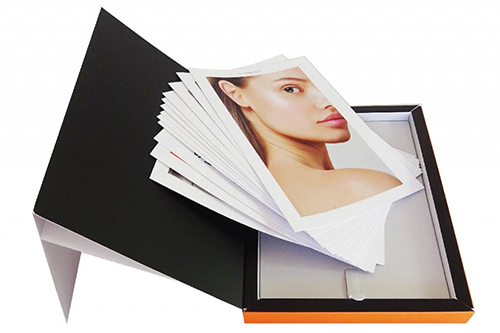

438 papers available to showcase your work in an extraordinary way

A variety of sizes, finishes and bindings to suit your needs

Competitive rates

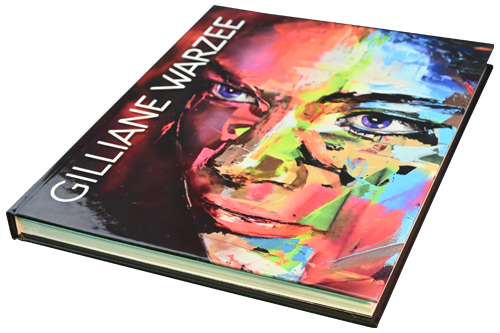

Make your book stand Out

The Options

Shelves for checkpoint of purchase

Production of promotional displays for the checkpoint area with unique design and full color offset printing. Our customers use these products to display a smaller number of products, most often near the checkpoint purchase of the retail outlet.

Floor Display

Production of promotional floor displays with unique design and full color offset printing. They are made of individual modules, easy to assemble and can bear a large weight, distributed evenly on the structure. They are used to display a large number of products, and can occupy a variety of locations in retail outlets or elsewhere so that they are sufficiently visible and convenient to use. Access to products may be from one, two, three, four sides.

Questions

Increasing your customer’s sales.

If you are looking to grow your sales within retail locations, free standing displays units will benefit both you and your customer by encouraging an increase in shop floor sales. Thus assisting in partner relationships. We need to know the business purpose that the promotional advertising display should fulfill – whether the purpose is to sell or to promote your product. Usually the promotional displays has a larger advertising area, i.e. it is more about the effect and not so much about the effective direct sale. On the other hand, the one aiming for a higher sales volume is more robust and the focus does not fall so much on the look.

Custom floor displays are very common in most types of retail and perfect for all types of products including food, beverage, health and beauty, pet supplies, and so many more. It is imperative to know what the product is that will be displayed on the display and what the target industry is. Are there different product lines that are intended to be used on the same display How will the products be arranged on the display horizontally or vertically?

Depending on the volume and weight of the products depends on the material and construction of the display.

Send us your PDF file with the drawing of the display construction and information on the most suitable display dimensions with maximum and minimum tolerances? Will there be additional features such as dividers, knobs or laminate for example.

What will the design be with detailed printing instructions and additional decoration options if available?

At Pulsio we can design and print cardboard displays with print runs from 1 to 20,000. For larger runs please contact one of our sales representatives.

The display travels to you folded with corners and stretchers in place, and placed on pallets . (1) We can put each module in a separate pallet and deliver them to the desired location where you can assemble them or distribute them to different sites. (2) It is possible to put a certain amount of display with all the modules needed for assembly in the same pallet. This is usually done if there are different points to which they are to be shipped and assembled.

The cost to build your display rack depends on a few key factors. These are:

The run

Of course, the run is important when it comes to forming the final price

The lead time

How long it will take to design the structure and design the print if you decide to outsource these activities to our team.

Printing and effects

The coating of the print and what technology is being used, as well as whether lamination, different foils and other enhancement effects will be applied.

Accessories

The cost is also influenced by whether the construction will require the use of various design and decorative elements.

Stages

1 – Idea

Most clients come to us with a clear concept and idea. We will guide you through the whole process, from design conception to delivery or installation. So wheater is one unit or 1000, Pulsio can provide a cost-effective solution for free standing display.

2 – Construction

In order to prepare an optimal price proposal, we need to know how the display rack will be constructed. For this purpose you have to send us PDF file with your design/drawing

3 – White Dummy

We will produce a white dummy for you (without printing and lamination). We create it so you can see in practice how the construction will look and whether it will meet your expectations in terms of functionality

4 – White dummy validation

The client validates the constructed design.

5 – Design

It is possible that the client has an idea for the design before the construction is made. If the construction is being made for the first time, the design may undergo some adjustments or a completely new one may be created.

6 – Validation of seal

We will send a digital PDF proof version of the display with the design applied to it for approval.

7 – Production of the display

After validation of the project electronically, we can proceed to the production of the entire print run – construction, printing, lamination, punching and other finishing.

8 – Packing and dispatch

We will fully comply with your packaging requirements and delivery points.

Useful Information

Constructions

2-, 3- or 5-layer corrugated board and micro corrugated board are used for displays

Mashing

Most often we print on GD board and less often we use GC for better printing or GT board for greater strength.

Conventional offset printing

Offset printing uses light-sensitive plates, usually made of aluminum, to transfer a combination of the four main ink colors (cyan, magenta, yellow, black) onto the printed media. In addition to CMYK, Pantone colors coatings and varnishes can also be used.

HUV Offset Printing

The printed sheet comes out with inks already dry, colors are overlaid for unparalleled print density resulting in excellent presentation, brilliance and brightness. Recommended for luxury items that by design need to be enhanced with hot foil stamping, UV spot varnish, etc.

Business purposes bring to us many different manufacturers and traders, but most often advertising displays we make for:

✔ Food industry,

✔ Health and beauty,

✔ Beverages,

✔ Household chemicals.

✔ Pet supplies.

✔ Other light industries.

Enquiry Form

Check our price: it’s free and it only takes seconds!